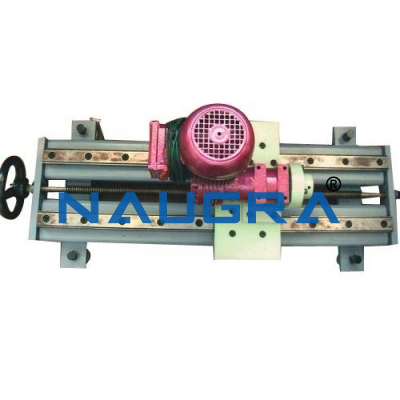

Fully Automatic Horizontal Line Boring Machine .

| STANDARD EQUIPMENT : |

| Permanent Parallels |

1 set |

| Parallels 130 mm High |

1 set |

| Parallels 160 mm High |

1 set |

| Parallels 200 mm High |

1 set |

| Bearings for Boring Bars (4 pieces) |

1 set |

| Tapered Centering Cones (4 pieces) |

1 set |

| Boring Bar |

30 x 1600 mm |

| Hardchrome-plated |

1 no. |

| Boring Bar |

48 x 1900 mm |

| Hardchrome-plated |

1 no. |

| Cutter Heads for: |

|

| 30 mm Boring Bar (OD 50 x 70 mm) |

1 each |

| 48 mm Boring Bar (OD 90 x 115 mm) |

1 each |

| Extra Support for Boring Bars |

1 set |

| Boring Bar Rest |

1 no. |

| Tool-setting Micrometer with Dial Indicator and Magnetic Base |

1 no. |

| Tool-setting Device for Cutter Heads |

1 no. |

| (Micrometer mentioned above may be used with it) |

|

| Centering Device with Dial Indicator |

2 nos. |

| Boring, Facing and Chamfering Tools |

26 pieces |

| Clamps, Bolts and Operating Tools |

1 set |

| Machine Lamp |

1 no. |

| Operation Manual |

1 no. |

EXTRA EQUIPMENT :

- Boring Bars with appropriate bearings, cones, extra supports and cutters 22 x 1300 mm and 60 x 2500 & 3000 mm

- Into-Bore Gauge (for measuring without removing boring bar) 35-105 mm and 100-210 mm

- Tool Grinder

- Extra Cutter Heads for 30 mm & 48 mm Boring Bars

- Extension for Boring Bar 260 mm

- Small Busing for extra support (specify diameter of boring bar)

- Boring Bar Sag Checking Attachment

- Bpring Bar Hand Feed Remote Control

|

| |

| SPECIFICATIONS |

| |

|

|

| Maximum Length of Block |

1550 mm |

2600 mm |

| Distance from Built-in Parallels to Boring Bar |

Maximum |

815 mm |

815 mm |

| Minimum |

515 mm |

515 mm |

| Boring Capacity |

| - With standard boring bars |

34 - 150 mm |

52 - 225mm |

| - With extra boring bars of 22 mm and 60 mm dia |

26 - 225 mm |

|

| Spindle Speeds (rpm) |

Infinitely variable from 50-750 rpm in two steps |

variable from 50 - 750 rpm in two steps |

| Feed: Both Directions (Automatic and manual) |

Roughing |

0.15 mm |

0.15 mm |

| Finishing |

0.04 mm |

0.04 mm |

| Maximum Travel of Boring Bar |

325 mm |

325 mm |

| Additional Travel with Extension Bar (extra equipment) |

260 - 325 mm |

260 - 325 mm |

| Drive Motor (440V, 50tn) Three Phase |

1.5 HP |

1.5 HP |

| (other standard voltages available on request) |

| Length of Machine |

3550 mm |

4850 mm |

| Width of Machine |

760 mm |

760 mm |

| Width of Bed |

570 mm |

570 mm |

| Maximum Height of Machine |

2200 mm |

2200 mm |

| Work Space required |

5050 x 1760 mm |

6000 x 1760 mm |

| Net Weight |

1700 kg (approx.) |

2200 kg. (approx.) |

| Gross Weight |

2200 kg (approx.) |

2850 kg. (approx.) |

|

|

| |

| Main Line Boring Machine |

| |

|

|

| |

|

This Machine is used for faster operation of Line Boring of the Main Bearings and Cam Shaft Bearings of Automobile & Tractor Engines. The bar supplied with the machine is made from special alloy steel and grounded to accurate size. The machine is supplied with all equipments required for full Operation.

STANDARD ACCESSORIES :

- 2 Pan Rails

- 2 Parrallel Flats

- Bridges (overhang brackets) 2 Nos.

- Acurately grounded bar 1 No.

- One Universal attachment.

- One double speed Gear Box, fitted with the pulley assemblies, can be adjust to required hight and direction.

- Pillars (columns) alongwith bushes for Shaft.

- Centring Plates (board to shaft size). Outside Dia. may be turned to the parent bore of Engine to be handled. 10 Nos.

- Taper Cones

|